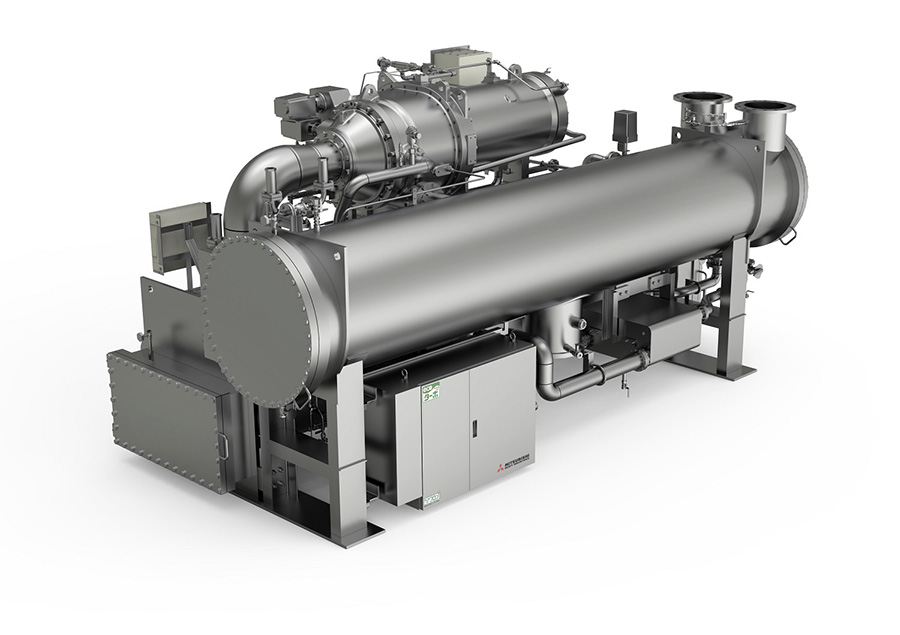

MITSUBISHI HEAVY INDUSTRIES THERMAL SYSTEM

FEATURES OF GART SERIES & GART-I SERIES

HIGH EFFICIENCY

Newly shaped compressor impellers

Improved evaporators and condensers

Adoption of a new two-stage-compression/ one-stage-expansion/economizer/sub-cooler cycle enhanced tracking of load fluctuations

APPLICATION

SEMICONDUCTOR INDUSTRY

Supply chilled water for manufacturing im- aging device like digital camera, LCD and semiconductors.

Supply chilled water for manufacturing im- aging device like digital camera, LCD and semiconductors.

CHEMICAL INDUSTRY

Chilled water supply for dehumidifying the air at deaerate pre-processing phase during the manufacturing process of oxygen and nitrogen.

Chilled water supply for dehumidifying the air at deaerate pre-processing phase during the manufacturing process of oxygen and nitrogen.

AUTOMOTIVE INDUSTRY

Supply chilled water to the drying oven of painting facility and other manufacturing process. Air conditioning system for the facility requires high cooling load and con- stant long annual operating hours.

Supply chilled water to the drying oven of painting facility and other manufacturing process. Air conditioning system for the facility requires high cooling load and con- stant long annual operating hours.

SPORTS FACILITY

Constant temperature and humidity control for making comfortable atmosphere at gymnasium and training facility. Ice making refrigerating machine at ice skating rink.

Constant temperature and humidity control for making comfortable atmosphere at gymnasium and training facility. Ice making refrigerating machine at ice skating rink.

CLEAN ROOM

Special control like temperature, humidity, air purification, air flow and air pressure of the room for the semiconductor factories etc.

Special control like temperature, humidity, air purification, air flow and air pressure of the room for the semiconductor factories etc.

DISTRICT COOLING

District heating and cooling systems (D.H.C) are made up of one or several local plants that produce chilled water and steam for cooling and heating a certain area and hot-water supply, and a network of supply pipes that deliver

these around the clock to a number of buildings. Centrifugal chiller is the core equipment of D.H.C system.

District heating and cooling systems (D.H.C) are made up of one or several local plants that produce chilled water and steam for cooling and heating a certain area and hot-water supply, and a network of supply pipes that deliver

these around the clock to a number of buildings. Centrifugal chiller is the core equipment of D.H.C system.

HOTEL / OFFICE

Constant temperature and humidity con- trol for making comfortable atmosphere at luxury hotels, and office.

Constant temperature and humidity con- trol for making comfortable atmosphere at luxury hotels, and office.

SHOPPING MALL

High efficiency is important in large shopping mall.

High efficiency centrifugal chiller and ice thermal storage system using centrifugal chiller are used,

because share of air-conditioning energy consumption is high for requiring annual cooling and constant long operation hours. The air-conditioning load largely depends on fluctuation of visitors number.

The problem is solved by variable speed drive chiller.

High efficiency is important in large shopping mall.

High efficiency centrifugal chiller and ice thermal storage system using centrifugal chiller are used,

because share of air-conditioning energy consumption is high for requiring annual cooling and constant long operation hours. The air-conditioning load largely depends on fluctuation of visitors number.

The problem is solved by variable speed drive chiller.

DATA CENTER

Requirement in air-conditioning system for data center is reliability, stable supply of chilled water and energy saving.

Supply stable chilled water with high effi- ciency and continuously.

Requirement in air-conditioning system for data center is reliability, stable supply of chilled water and energy saving.

Supply stable chilled water with high effi- ciency and continuously.

FOOD INDUSTRY

Prevent breeding various germs by cooling rapidly with nearly zero degree chilled water during process of sterilization of the mineral water manufacturing facility. Also apply to cool down the water during process.

Supply stable water temperature of 10 to 30°C chilled water for cooling down manufacturing machinery.

Prevent breeding various germs by cooling rapidly with nearly zero degree chilled water during process of sterilization of the mineral water manufacturing facility. Also apply to cool down the water during process.

Supply stable water temperature of 10 to 30°C chilled water for cooling down manufacturing machinery.

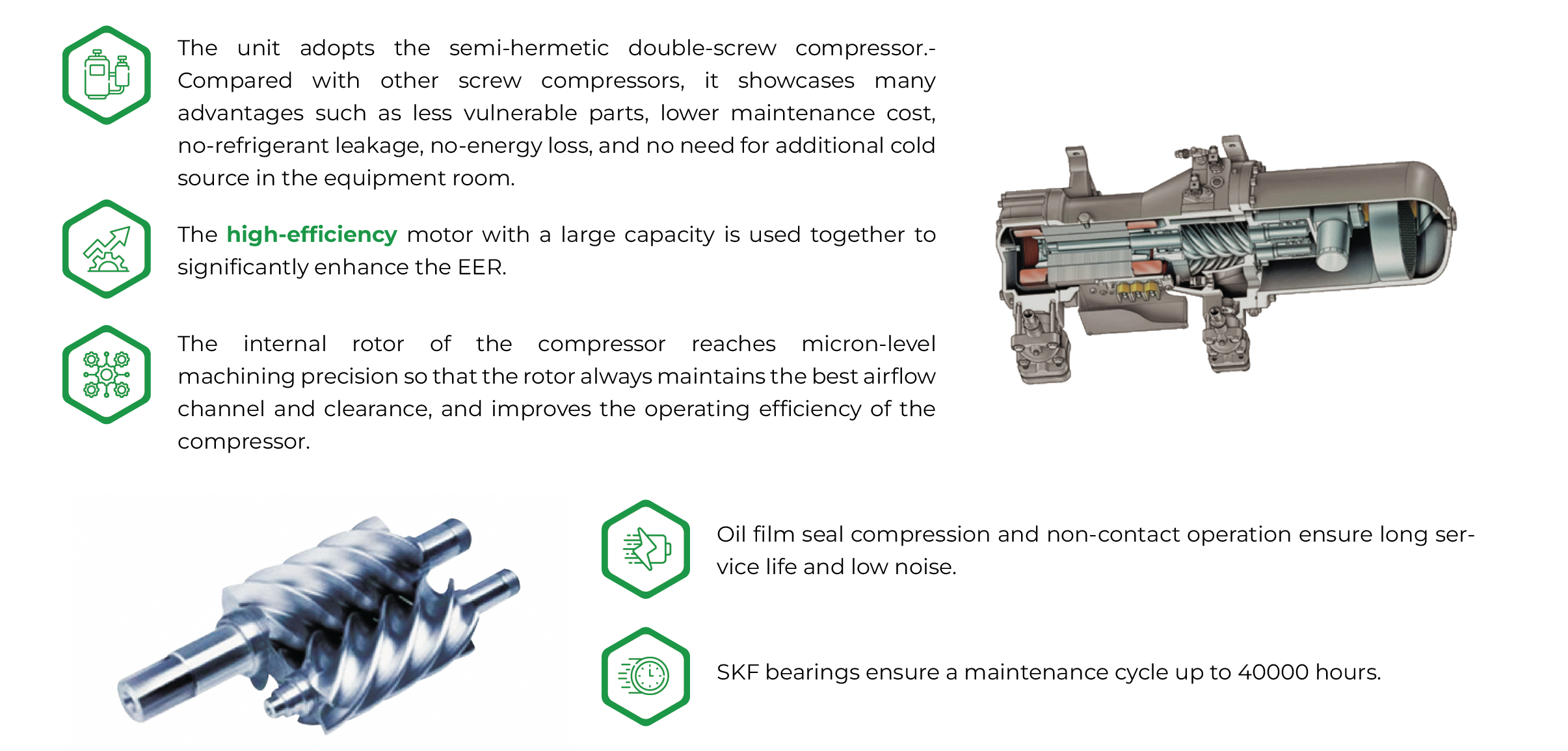

COMPRESSOR

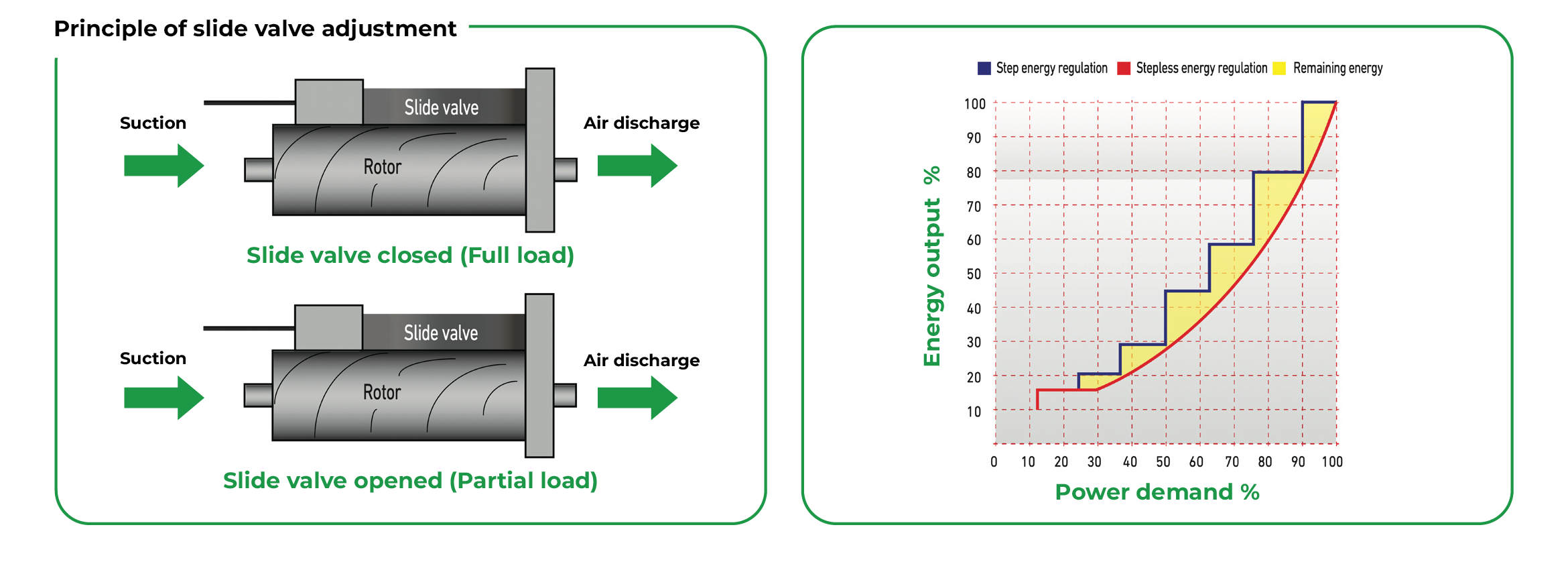

STEPLESS CAPACITY REGULATION

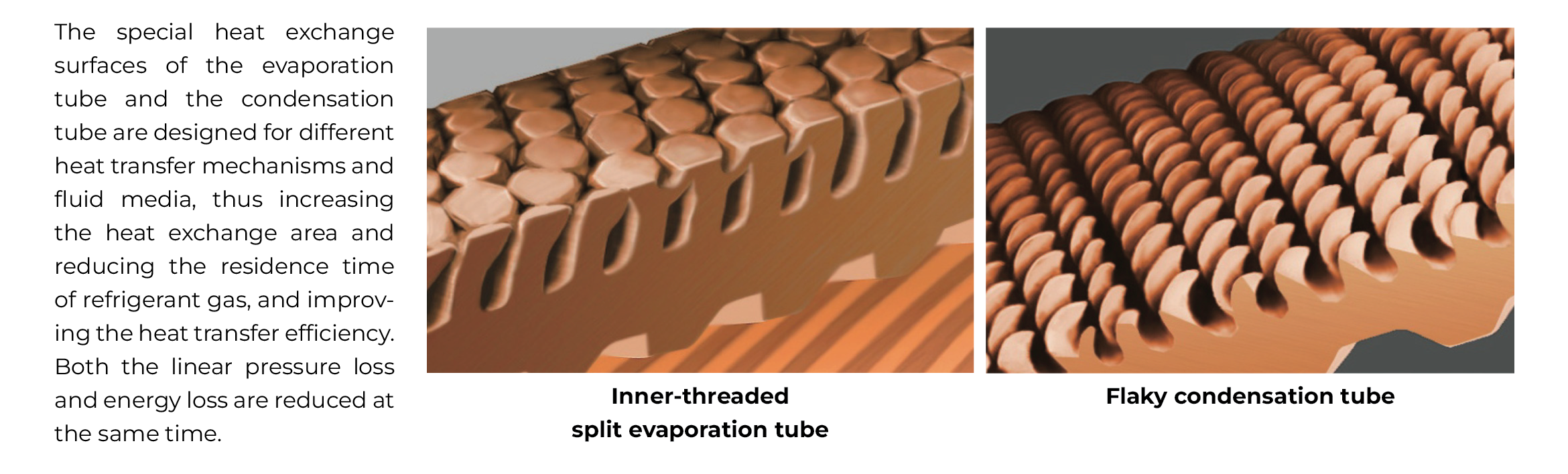

HIGH-EFFICIENCY HEAT EXCHANGE